Optimizing Assembly Efficiency with a 1 Ton Electric Chain Hoist

Material Handling Solution for Light Manufacturing Plant | Asia

Project Overview

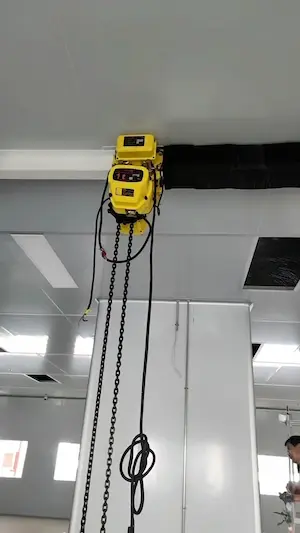

KYLIFT successfully delivered a comprehensive material handling solution featuring a high-performance 1 ton electric chain hoist for a light manufacturing assembly plant. By mounting the hoist on an overhead steel beam, the facility transitioned from manual labor to a precision-controlled automated lifting system, drastically improving daily assembly cycles.

⚠️ The Challenge

The client’s workshop relied on manual material handling. This bottleneck led to frequent downtime, inconsistent assembly speed, and increased physical strain on workers moving heavy components.

The Kylift Solution: Precision Industrial Hoisting

We implemented a Fixed-Type Electric Chain Hoist engineered for durability and safety:

- ✓ Capacity: 1 Ton (Heavy-Duty)

- ✓ Lift: Customized Vertical Height

- ✓ Power: 380V/50Hz/3Ph Industrial Grade

- ✓ Chain: High-Strength Alloy Steel

Operational Impact & Results

- 🚀 Efficiency Gain: 35% increase in component positioning speed.

- 🛡️ Safety Record: Zero manual lifting-related incidents post-installation.

- ⚙️ Reliability: 24/7 stable operation under continuous duty cycles.

Ready to Upgrade Your Workshop Safety?

Contact our engineering team for a custom quote on lifting solutions tailored to your specific facility dimensions.